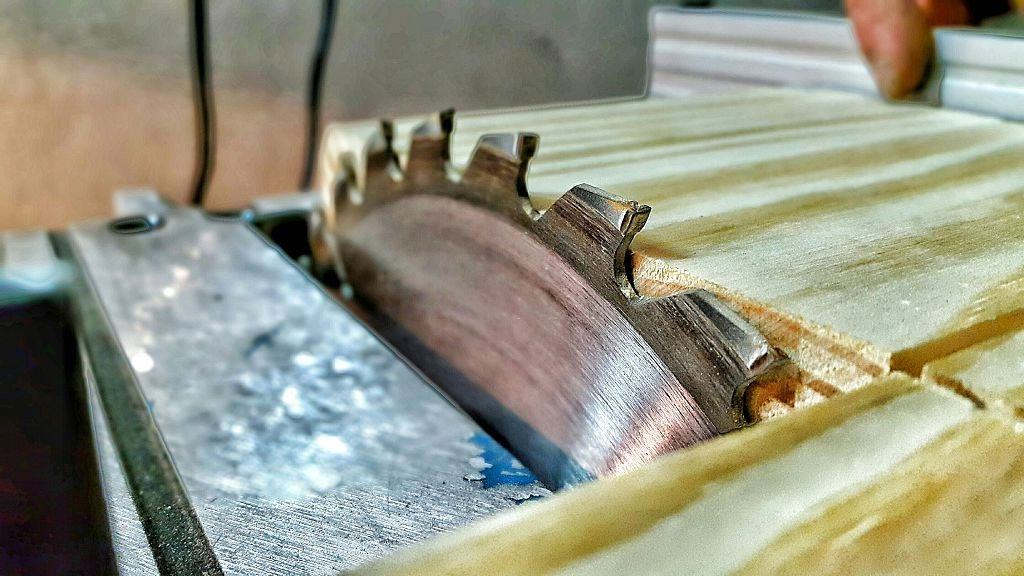

Of course, you would agree with me that the major part of any saw is the blade.

Speaking about Miter saws – if you want to make those accurate crosscuts and miter cuts of your desire in a workpiece, then you would definitely need a saw blade and not just a blade, but the best.

You need not look far if you are looking for the best Miter saw blades as we have taken the pain to help with the search.

Hence, we bring you a list of the carefully selected top 7 Miter saw blades you can find in the market today.

More...

Read more —

Best Miter Saw Blade On The Market: My Top 7 Choices

Freud D12100X Diablo's next-generation 12-inch X100 tooth ultimate flawless finish carbide circular saw blade is not just another kind of saw blade but quite an amazing saw blade to use.

This miter saw blade has gained a position as one of the popular miter saw blades around.

The price may be high as probably expected, but trust it’s worth the money as it offers fantastic features.

The Freud D12100X features new laser-cut stabilizer vents perfect for accurate and precise clean cuts in wood materials.

With the advanced new laser-cut stabilizer vents comes permanent filler baked in from top to bottom as a noise absorber and it also helps to prevent sideway movements when cutting.

It allows the blade to slice through the piece of wood quickly creating an accurate and clean cut.

For the design and construction of the saw blade, the material used is TiCo Hi-Density special-blend carbide. With an ultimate flawless finish that makes any cut you desire just a piece of cake.

It makes delivering cuts on the workpiece very effortless that you won’t have to worry about wasting materials.

The operation is just as smooth as using a heated samurai sword on butter. Hardwood materials are not much of a problem when it comes to this miter saw blade.

There is also a laser cut heat expansion slot that allows for the expansion and contraction of the heat blade while in use, to keep the cut straight and true – I guess you remember “linear expansivity” in physics.

The blade is perfect for cuts done on pre-finished materials, delicate molding, Stair, and banister construction.

- It is used for accurate and precise cuts

- The cuts and finishes are smooth and clean

- High-grade blade quality and design

- Multiple functionalities

- It comes with laser-cut stabilizer for trapping vibrations and noise during work

- Slightly expensive

- Little rough on softwood

Hitachi, being one of the widely known saw blade producers, also known for a good quality product, yet offers another product that is recommendable.

This product is good for cross-cutting ultra-fine and smooth finishes in veneer, decorative moldings, laminates, and soft and hardwood floors.

The durability is one special feature that cannot be overlooked.

Also, the miter saw blade features a tungsten carbide tipped teeth. This serves as an alternate top bevel blade which allows the blade to withstand years of repeated use, and of course, outlasts traditional blades.

Ordinarily, the Tungsten carbide construction material is known for giving saw blades a sharper and long-lasting tip. You know what!

A lot of people have complained about the wood piece tearing while sawing, glad to tell you that you will not experience this with Hitachi 725206 72-Teeth Miter Saw Blade. It creates amazingly clean and smooth cuts without even the outside wood tearing off.

Besides, if this is what you’ve been looking for, a period of 30-day warranty is given to the original purchaser starting from the original purchase date.

- Highly durable and dependent

- Produces Smooth, Quiet Cuts with Laser-Cut Kerf

- Shock-Resistant Carbide for Long-Lasting Precision

- Permashield Coating

- Leaves no splinters

- Ideal for cabinet making

- The teeth are rough on softwood

You have your budget fixed already, or you probably cannot afford to buy the expensive ones?

Well, we had you in mind as well.

Like I always say, not everything that is relatively cheaper is lesser in quality.

Of course, you might find more features in the expensive ones, but it still doesn’t mean you can’t have something good for just the cash you have at hand.

Makita A-93681 is undoubtedly a good quality saw blade on Amazon's best sellers list.

Some of the fascinating features this low budget miter saw blade offers include ATAF (The Alternative Top and Alternative Face) tooth designed for ultra-precision cutting and micro-grain carbide teeth which are honed with up to 600 grit for a mirror finish.

This product also gives smoother cuts with less drag on the motor and helps to reduce material loss – thanks to the Japanese Ultra-Thin Kerf Carbide-tipped design.

- High quality for a small price

- Designed with quality carbide material making it durable

- The blade is sharp and provides thin, smooth cuts

- Smoother cuts with minimal material loss

- Blade performs well, but it is noisy

- It cannot be used to cut metal

Naturally, we want our blades sharp and ready to cut. Still, that won't do you any good if the overall quality of a blade is low and it can't hold up to some tougher materials.

So, here's one of the most durable blades out there, the NEIKO 10768A 12" Miter Saw Blade.

This saw blade measures 11.97 x 11.97 x 0.38 inches, and it weighs 2.54 lbs. The reason we mention this is closely related to the fact that its 80-tooth design allows it to make extremely smooth cuts and finishes across the grain, and that wouldn't be possible with a bulkier and heavier blade.

These blades are carbide-tipped, which gives them excellent resilience in terms of high heat at faster speeds.

Also, abrasion won't pose any problems when you use this blade on a miter saw, meaning you'll still be able to cut without making any pauses to clean off the material or the blade.

This is an industrial-grade blade that was tested multiple times to ensure the quality and overall resilience are up to par with other premium blades on the market.

It'll retain its original design and appearance even after continuous use, no matter the material you're using it for.

Speaking of, it was tested with different types of wood, metal, and plastic and still passed with flying colors.

Thanks to the 80 teeth on the outer edge, you can cut at high speeds and get the desired results, even with beveled cuts.

Most importantly, it's very affordable and great to have, even as a replacement blade to the one you currently own.

The only flaw is that it can burn specific types of wood at higher speeds due to its sharpness. If you're using a low-quality stock, make sure to adjust the speed below 3500 RPMs to get the perfect cut. It will take you more time, but it'll pay off.

- Lightweight

- Durable and resilient

- Made for continuous use

- 80-toothed carbide tips

- Exclusive use with quality stock

If you're dealing with delicate and rough stock that requires more time to cut, you'll need a blade with fewer teeth that can operate efficiently at lower speeds. Therefore, here's the best 5 ½-inch blade out there, the IRWIN Tools MARATHON Blades.

Naturally, the dimensions of this blade are significantly smaller compared to the previous products.

It measures 7.2 x 7.2 x 0.1 inches, weighs only 0.25 lbs, and has 18 teeth on the outer edge. The resulting kerf from the cutting process is incredibly thin; therefore, you'll have more cuts and improve the overall lifespan of the blade.

Also, if you're using a cordless miter saw, this will significantly affect its battery life since you'll have more cuts per charge.

Even though you'll use it for tougher materials, it can still deliver fast cuts with standard stocks, thanks to the strong carbide tips and its construction-grade design. It's mostly used by contractors that work on the field with cordless circular and miter saws.

Irwin has a wide selection of miter saw blades, and this is just one of the models you can order from their website and Amazon. In terms of miter saw blades, you can choose a size anywhere between 5 ½-inches and 8 ¼-inches.

All in all, they're all great for framing, ripping, and delivering smooth cuts on boards and metallic stocks.

However, you have to keep in mind that the overall cut will be a bit rougher than with the previous blades, simply due to its smaller nature and fewer teeth.

If this isn't a deal-breaker for you, these Irwin blades will work wonders for you.

- Thin kerf

- Fewer teeth for tougher materials

- Works efficiently at higher speeds

- Wide selection of different sizes

- Rougher finishes in comparison with the previous blades

Another option to consider is the DeWalt DW3128 80 tooth crosscutting miter saw blade.

The blade is made of a thin kerf to deliver fast, smooth, and accurate cuts.

One special feature of this miter saw blade is the computer balanced plate designed to reduce potential vibration for improved accuracy and better finish while cutting.

It is ideally a general-purpose kind of metal saw blade, and it also has a great price offer.

The blade with tungsten carbide material is highly durable, which means that you are going to get a lot of work done with this blade for a very long time.

- Computer balanced plate design

- Anti-kickback shoulder helps to prevent binding

- Thin kerf which facilitates smooth and fast work

- The teeth are ultra-sharp

- Ideal only for wood cutting

- Blade dulls very quickly

- May not work well on hardwood flooring

This miter saw blade comes with a number of laser-cut anti-vibration vents that provides truer and straighter cuts.

The construction of this metal cutter is done with metal-cutting grade carbide teeth aimed at high durability.

It also comes with anti-kickback tooth shoulders for improved safety. It is the best selection ideal for cutting thin metal.

The Irwin 4935560 7-1/4-Inch 68-Tooth Metal Cutting Circular Saw Blade is an industrial tool designed for cutting thin steel and your high gauge metal cutting needs.

The durability is well kept in mind as it comes with metal cutting carbide tips for smooth and fast cuts.

This Irwin blade is designed to reduce material loss, wear, and it is able to withstand strong impacts and provide longer life.

The construction includes a well-stabilized blade intended for smooth and accurate cuts.

It also features an anti-kickback design which helps to reduce dust and sparks for a safer cut.

- Highly durable

- Reduces wear and material loss

- Ideal for framing and drywall needs

- Laser-cut blade

- Produces fast cuts

- Anti-vibration vents

- Good protection is needed when using the blade

- Pretty expensive

Things to Consider When Buying a Good Miter Saw Blade – The Buyer’s Guide

Have you ever tried to buy something off the market but you probably didn’t have enough information as to what it is you should consider when looking for the best?

Well, here we will be discussing how you can get to choose just the best, and the right miter saw blade for yourself.

Here are the things you should look out for when selecting the best miter saw blade.

1. Type and Material of Blade

This quite an important factor to consider when selecting a good miter saw blade. The type of blade actually plays a vital role in how well the saw blade performs.

We have about three types of blade available: steel, high-speed steel, carbide-tipped blade.

2. Blade Size

There two sizes of the miter saw blades you’ll find in the market today: the 10 and 12 inches blade. You will also find some blades that can be adjusted with all miter saws.

However, the quality of the cut depends on the size.

The 12-inch blades are the best options for you if you want to work on wood. The blade size determines other things like the number of teeth and blade design.

3. Number of Teeth

Typically, the minimum number of teeth for a regular miter saw blade is about 30 teeth, and the maximum can be as high as hundreds depending on the size on the size of the blade.

It is important to note that the more the teeth the blade has, the cleaner the cut would be.

The blade sure takes a small piece of the material with each pass of the tooth per time. Imagine you have hundreds of tiny teeth to work, be sure you would get a cleaner cut. The lower number of teeth is significant for folks who want to achieve rough cuts.

Also, the fewer the teeth, the more significant the gaps that would be left when cutting. With each pass of a tooth, a big chunk will sure be removed from the material as you cut.

4. Blade Design

The blade design plays a major role in whether you would have a noisy workshop or not.

Good blade designs help to reduce noise and vibrations caused by the cutting process. Technically, the blade design determines the blade stability too.

5. The Kerf

The kerf of the blade you use for your cutting also determines the thickness of the cut. It is particularly ideal for removing a significant chunk of material faster.

The thinner the kerf of the blade, then the better the precision that would be made.

However, in this case, the cuts are usually a lot slower to make.

No products found.

Sawing Tips That You Might Need

In addition to the sole aim of this article, we would like to present to you some sawing tips.

Of course, whatever cutting you want to achieve with any type of saws will be done mostly by the saw blade.

However, if you want to achieve the safest and smoothest cuts, it is important that you become a very careful saw operator.

Below are a few essential tips.

1. Steps to Setting Up Your Saw for Success

Firstly, check to ensure the left and right fence sections are coplanar.

You can experience dangerous cuts which can result from vibrations caused by a lack of support on either side of your workpiece.

Also, check to ensure the surfaces of the fence is perpendicular to the saw’s table by checking all the few inches along the fence with a precise square.

Now that the fence is tightened in position, square the blade to the fence. After this, calibrate the zero-degree marker on the scale of your miter saw to the position.

You will have to follow the same procedure with the setting of the bevel while ensuring that the blade squares with the table of your saw.

Check the center of the table to ensure that the plastic insert flush with the surrounding metal surface. If it doesn’t, shim up the plastic insert.

If you don’t do this, a flexible or short stock might result in burning of the cuts.

2. Make a Zero Clearance Cutting Surface

You might have to attach hardboard strips to the table and the fence with double-sided tape.

To support the piece you’re cutting fully, ensure the strips of hardboard cover just enough area. The only trouble you might have with this is that the strips can require replacement when you change the angle of the miter.

To help with this, you can cut the zero clearance table inserts out of hardboard. The only thing is that it might be quite difficult to cut them to shape.

Also, this may cause the side of the work to be prone to a splintery blowout and unsupported.

3. Never Let the Teeth Touch the Work Twice

Carelessly cutting through a workpiece has been the major cause of two problems known with miter saws.

One is the small cutoff pieces sent flying around in the air by the blade and the second is ragged edges at the top of a cut.

To avoid these two problems, follow this simple advice.

After completing a cut, ensure the blade is held down until it comes to a stop completely. Then, do not allow the teeth of the blade to touch the work as it winds up.

Always ensure that the workpiece is set in position before bringing the miter saw blade in contact with it.

Frequently Asked Questions

Here are some answers to common questions people ask about miter saw blades.

Can you cut metal with a miter saw blade?

Yes, you can cut metal with a miter saw blade depending on the kind of blade.

Check through the previous section to know how to identify miter saw blades suitable for cutting metals.

However, the best blades for cutting aluminum are carbide-tipped blades.

It should be noted that if you use the blade to cut metal of large amount, more wearing out of blades will occur.

What is the best blade for a miter saw?

It has to be the Freud D12100X 100-Tooth Diablo Blade.

It can deliver various finishes with adjustable speeds, it's durable, and will not disappoint for any project.

Which is the perfect circular saw blade that works best?

If you want excellent performance, the high-speed circular blade is a solid choice. You will get clean cuts and less sawdust.

Beyond that, it helps to reduce waste of materials.

What type of saw blade should you use for ripping?

We have different types of saw blades as you probably know already, but when it comes to ripping, a rip blade will come in handy. This is because it features teeth with a flat top.

These are used and good for ripping woods that are both hard and soft.

Does the teeth configuration matter?

The design or the configuration of the teeth is very important when it comes to making clean and right cuts. For example, you may need a flat top configuration for rip cut.

Does a blade with a higher number of teeth mean a better option?

Well, it depends on the kind of cuts you want to achieve. You can get smoother finishes with more teeth. They also produce less dust.

On the other hand, fewer teeth can be a good choice for cutting thicker material like metal.

Final Verdict

You can now agree with me that even though getting the best miter saw blade is not an easy task, it is not impossible.

After checking out the saw blade options provided above and some other helpful information, I believe you can now pick the best blade for your miter saw.

Note that buying a terrific miter saw with advanced features doesn’t make so much sense. Having the best miter saw blade is not a negotiable factor in achieving the best cuts.

No products found.